Customer Satisfaction

Continuous Improvement

The company upholds a dedicated attitude, uses the company's expertise, continuously innovates technology, develops new products, strengthens core technologies to improve the company's competitiveness, and is committed to providing customers with high-quality, low-cost products; through full participation in quality management and Continue to improve, create employee well-being, provide a good working environment and system, let employees enjoy their work, and pursue better performance; provide smooth communication channels and dialogue with stakeholders, abide by laws and regulations, friendly environment, control risks and grasp Opportunities, the pursuit of higher profits to maintain the company's growth, in order to achieve the purpose of corporate sustainability.

Quality Management Process

Control

Control

Assurance

Product Quality Management

- Potential Failure

Mode & Effect

Analysis - Control Plan

- Statistical

Process Control - Measurement

System Analysis - Continual

Improvement

Quality Control Capability

Spectrophotometer

Use a high-precision spectrophotometer to digitize color value (L*a*b and total color difference ΔE*), so that it is easier to accurately measure products to meet design specifications and customer requirements.

Glossmeter

The gloss meter can measure the material surface from three different angles, record the reflective degree of the surface in a digital form, and confirm whether it meets the design specifications and customer requirements.

Battery Tester

Use the battery tester to measure and analyze the capacitance, inductance, and resistance of different types of batteries. The high accuracy and measurement range help confirm whether the material meets the design specifications and requirements.

Image Dimension Measuring System

Use 2.5D measuring equipment to assist the position and angle of existing measuring tools that are difficult to measure, to ensure that the relative size of the product meets the requirements of design specifications, so as to maintain quality consistency and process stability.

Drop Tester

Simulate the impact on the product when the package is dropped, and verify everything in the product development stage

Power Test Laboratory

Through a high-power audio source, simulate the aging process of the product to confirm whether it meets the design requirements, so as to evaluate product safety and future R&D and design directions

DC Power Supply

Use DC power supply to the overload test.Provide controllable and stable power supply in detection or experiment

LCR Meter

Use the LCR meter to perform the measurement and analysis of capacitors, inductors, and resistors. The high accuracy and measurement range of the LCR meter can help confirm whether the material meets the design specifications and requirements.

Environmental Test Machine

Environmental Testing Machine Through the test of the environmental testing machine and in a way that is closer to the actual situation of use, we can evaluate the tolerance and aging degree of the product to high temperature and high humidity to confirm whether it meets the design requirements, so as to evaluate the product’s life and the future R&D design direction.

pray Tester

The salt spray test is one kind of environmental test, mainly used to evaluate the corrosion resistance of products or metal materials. It tested by the prepared brine and used to simulate the influence of the seawater environmental on the product.

Vibrating Test Machine

Vibration test equipment is mainly used to simulate whether the transportation situation of the product will affect the product when it is packaged or unpackaged.

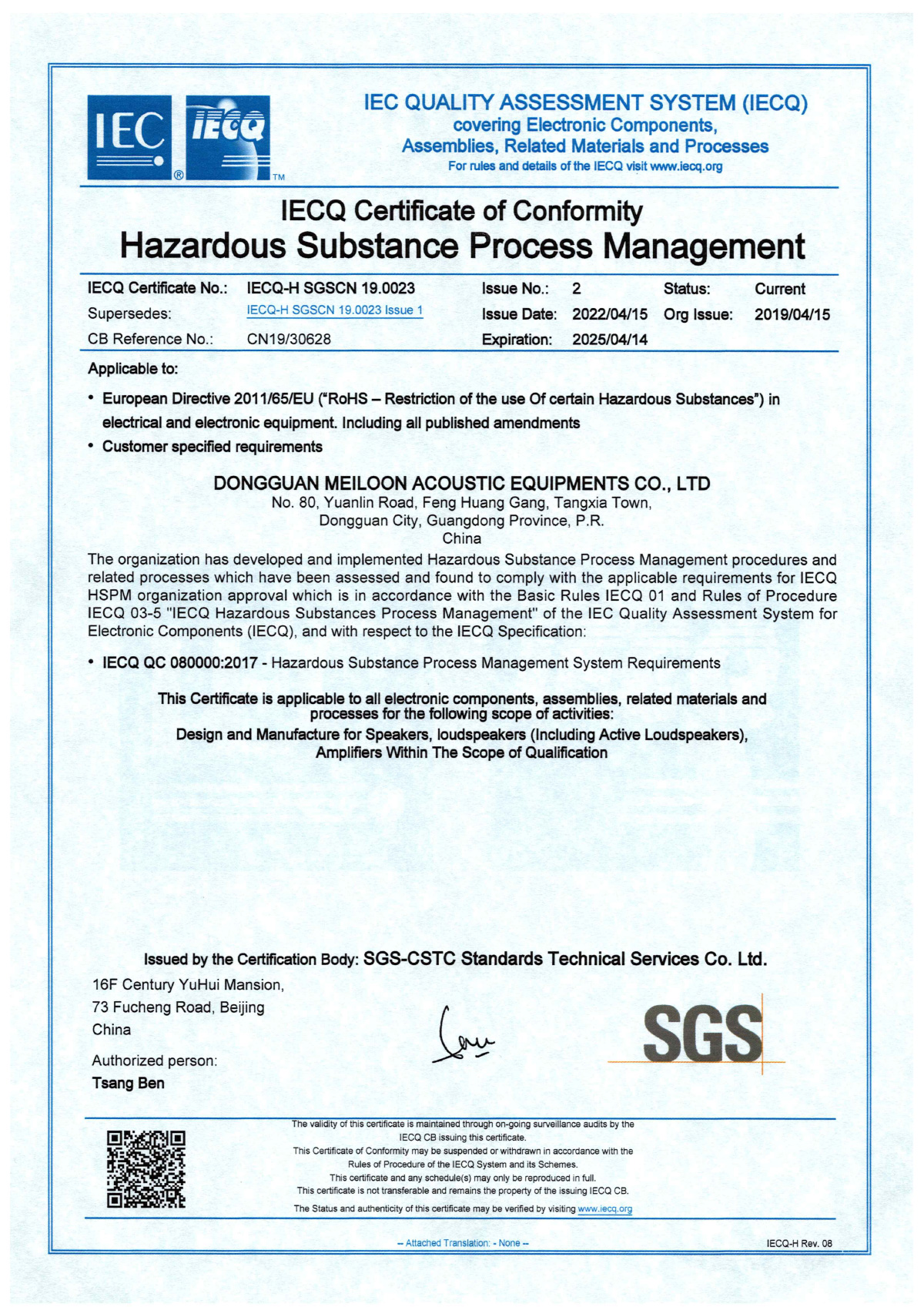

XRF

RoHS testing equipment, analyzing the six major harmful substances in the product, and complying with QC080000 regulations